-40%

Low Cost Small Pick and Place Machine Vision System NeoDen3V-Std 23 Feeders

$ 2375.47

- Description

- Size Guide

Description

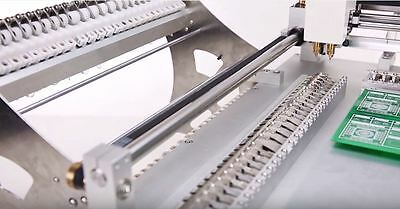

Desktop Pick and Place Machine with Dual HeadNote: tariff, tax, local fees and local support are not included.

Item Description

NeoDen3V is a latest version designed on the basis of TM245P series.

It features dual head, 44 feeder slots, vision system and flexible positioning system, which is suitable for prototyping, small-medium batch production with stable performance and affordable price.

NeoDen3V-Standard &

NeoDen3V-Advanced

Please kindly note there are two versions of NeoDen3V, standard and advanced, the only difference is the advanced version has extra 19 back side tape feeders.

Tape feeder

qty

of standard version:left side-18*8mm,4*12mm,1*16mm;no back side feeder

Tape feeder

qty

of advanced version:

left side-18*8mm,4*12mm,1*16mm;back side-15*8mm,2*12mm,2*16mm

Contact Cathy Lee to get more special offer.

Specification

Model

NeoDen3V-Standard

Machine style

Single gantry with

2

heads

Alignment

Vision System

Placement Rate

5

,000CPH(vision off);3,500CPH(vision on)

Feeder

C

apacity

Standard version

23

(

18*8mm,4*12mm,1*16mm

)

Advanced version

42

(

33*8mm,6*12mm,3*16mm

)

Vibration feeder

:5

Tray feeder

:5

Component

Range

Smallest

S

ize

0

4

0

2

Largest

S

ize

22

x

22

mm (Lead Pitch 0.5mm)

Max Height

5

mm

Rotation

±180°

Placement

Accuracy

±0.0

2

mm

X-Y

R

epeatability

±0.0

2

mm

Board Dimension(mm)

Maximum

32

0

x

4

2

0

mm(

Standard version

)

32

0

x

390

mm

(

Advanced version

)

Main Control

GUI

E

lectricity Supply

110V/220V

Power

16

0~200W

External Dimensions

(mm)

Standard version

1001(L)x961

(W)x568

(H)

Advanced version

1001(L)x961(W)x568(H)

Weight

Net Weight

55

kgs

Gross weight

80

kgs

Features

1.

Full vision 2 heads system

could satisfy the demand of wide range components and high accuracy.

2.

Patented electromagnetic

actuators

, you don't need to get rid of the wasted nylon film manually, which saves you more time and effort.

3.

Vibration feeder

that can support to handle

tube

packaged

components

;

4.

Flexible PCB positioning

function by using PCB support bars and pins, wherever you want to put the PCB and whatever the shape of your PCB is, all can be handled well.

;

5.

Integrated

Control

le

r contributes to more stable performance and easier to do maintenance.

How to Program

A. Generate coordinate file from PCB design software (AD, Eagle, KiCad,Upverter, etc)

1. Take the software

Altium Designer 6.9

as an example

,

from which we can generate a csv. file.

2. Edit the generated coordinates file to make sure the machine could read.

Copy the file into a flash drive, then import it into NeoDen3V.

This whole process only takes 3 minutes.

B.Manual programming

If you don't have PCB layout, you can also easily program

a working file

with the assistance of vision system,

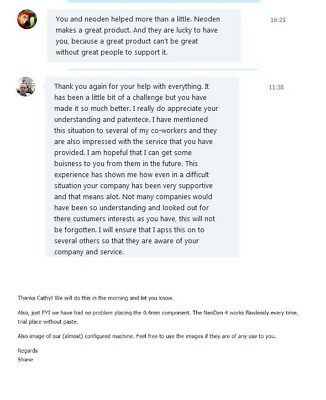

Feedback

Overall we are quite happy with our machine. We assembly some very complex boards with lots of 0201,0.5 QFN and even some 0.4 BGA components.

——Mario van Asselt

The machine has been great and we are very pleased with it so far.

——Ian

Also, just FYI we have had no problem placing the 0.4mm component. The NeoDen 4 works flawlessly every time.

——Shane Goedvolk

About us

1. NeoDen is a professional designer and manufacturer of desktop pick and place machine with 30 patents and CE certificate.

2. Total 8 Agencies in Japan, India, Netherlands, South Korea, Iran, Turkey, Brazil and Chile, which helps to provide direct service

and better communication in local territories.

3. The after-sale service team consists 14 professional engineers, which helps to respond customers queries and enquiries within 8 hours, provide

professional solutions within 24 hours both workday and holidays.

4. NeoDen use standard export packaging, which is the recycled wooden crate,

not only safer in transportation but also better in environmental protection.

Payment and Delivery

1) Payment

method

: PayPal, West Union, Credit Card, etc

2)

The default delivery method is via TNT (door to door), unless specific requirement from customer.

3) Delivery time: 2-3 working days.

Warranty

The

guarantee

period is 1 year from the time of purchase and lifelong service support as well as a long-term factory price supply.

NeoDen will

provide online Q/A and troubleshooting support and technical advice service.

Welcome to check more items in our store.